The company discloses the extent to which natural resources are used for the company’s business activities. Possible options here are materials, the input and output of water, soil, waste, energy, land and biodiversity as well as emissions for the life cycles of products and services.

As a non-producing company operating on rented office space, cosnova GmbH has limited influence on its own use of natural resources. The most relevant resources for cosnova include:

In the following, the individual areas in which environmentally-relevant data are already collected and optimized are explained in detail.

Sulzbach Office Site

At the Sulzbach office site, the energy consumption, amount of kitchen waste and paper usage are recorded. In 2015, an energy audit was carried out at the Sulzbach site in accordance with legal requirements. Due to the rental situation, this only resulted in a few potential savings, as the systems technology is located in the building and is not under the control of cosnova GmbH.

Butzbach Logistics Site

The new CNL Logistics Centre was built in 2016 in accordance with the EnEV standard (Energy Savings Regulation). Various other measures were also implemented to make our logistics processes more environmentally-friendly and a Lean and Green program was launched. In addition, an extensive project was carried out to optimize and reduce the logistics waste generated at the site and to optimize the use of shipping cartons.

CO2 emissions in the cosnova business model in general:

The business model of pure contract manufacturing requires long, upstream transport routes, as the globally manufactured products have to be transported to the warehouse of the logistics partner CNL. The data collection of these transports is currently not possible, which severely limits the concrete possibility of influencing these outsourced processes. The following processes are affected:

Emissions at the Sulzbach site:

Relevant CO2 emissions at and due to the Sulzbach site are mainly caused by business trips, electricity consumption and heating as well as, to a comparatively small degree, by the company's own vehicle fleet, the disposal of the waste produced and the commuting distances of employees.

Emissions at the Butzbach logistics site:

Relevant CO2 emissions at the logistics site are caused by electricity consumption, gas consumption and downstream transport routes. The construction of the new logistics center has made it possible to implement a number of CO2 -reducing measures. Gas consumption and the resulting emissions have decreased significantly compared to the old site, despite the larger usable area in the new warehouse. The reduction in gas consumption can be explained by the installation of special dark heaters in the ceilings of the logistics center as well as the optimized insulation of the hall ceilings and walls. All of these measures are aimed at reducing energy consumption at the logistics site and conserving energy resources. In addition, there will be a conversion to certified green electricity from renewable resources on 01.01.2019.

Energy at the Subzbach site:

The type of electricity as well as the electricity consumption can also be directly influenced in rented office space. cosnova GmbH already switched to green electricity from renewable energies quite some time ago and started implementing smaller energy-saving projects in 2014. These include a comprehensive conversion of the bathroom lighting to motion detectors and, for example, the conversion of daylight luminaires to special motion-activated floor lamps over the entire rented office space.

Energy at the Butzbach logistics site:

During the construction of the new CNL logistics center, all lighting was converted to LED technology due to the higher energy-efficiency of LED lamps compared to conventional light sources.

Water: Water consumption is neither relevant for the Sulzbach site nor for the logistics center and is therefore not recorded.

Waste at the Sulzbach site:

Since the Renewable Energy Sources Act (Erneuerbare-Energien-Gesetz - EEG) came into force, electricity production from biomass has grown strongly. We also participate in this process by recycling the kitchen and food waste from the company's own canteen in a biogas plant. All other waste generated at the site is disposed of directly by the landlord and is not within the scope of control of cosnova GmbH.

Waste at the Butzbach logistics site:

The waste generated at the logistics site is part of an extensive waste optimization and reduction project. In addition to a general waste reduction, we have set ourselves the goal of identifying alternative materials with a reduced ecological footprint as well as of finding the best possible recycling solutions for the remaining waste through recycling or upcycling projects.

Paper at the Sulzbach site:

The paper consumption at the office location is recorded annually, qualitatively it is fresh fiber paper, which is 100 percent PEFC and EU Ecolabel certified. Various interdepartmental projects have been initiated to reduce paper consumption, for example, the introduction of a "chip for all systems" on all printers, which avoids unnecessary printing. Other activities include the general presetting of printers to double-sided printing or the introduction of an electronic invoicing system in the Accounting Department. For two consecutive years, introducing these measures has led to a reduction in total paper consumption of more than 20 percent. In the long-term, cosnova GmbH is aiming for a completely paperless office.

Paper at the Butzbach logistics site:

In order to reduce the paper consumption at the logistics site, further concrete projects have already been initiated in addition to the general aim of reducing waste, which also includes the reduction of paper consumption. For example, by minimizing the wall thickness of the cardboard used or setting up a small internal print shop. With the help of this in-house print shop, assembly instructions and other documents can be printed piece by piece, thus avoiding unnecessary printouts that were previously not avoidable when ordering from external partners.

Cosmetic raw materials:

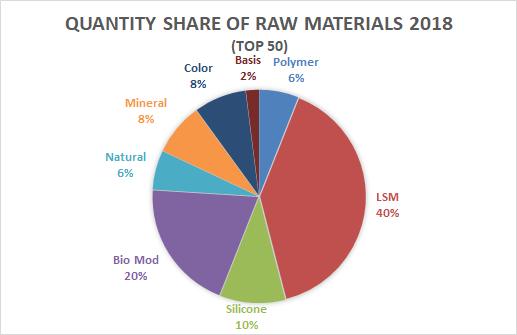

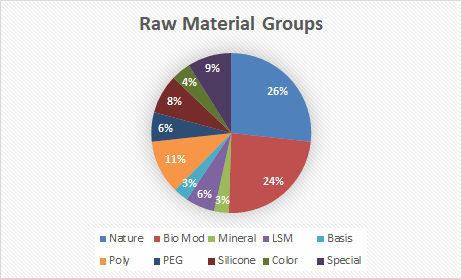

A wide variety of natural resources in the form of cosmetic raw materials are used to manufacture our products. According to our internal raw material cluster, these include natural substances, biologically modified substances and mineral substances. Natural substances and biologically modified substances have the largest diversity of raw materials.

Looking at the quantitative share of raw materials in the finished products, the category of biologically modified substances accounts for 20 percent of the total raw material share, natural substances for 6 percent and the category of mineral substances for 8 percent. Consequently, one third of all raw materials used have a natural origin or can be considered near-natural.

- Cosmetic raw materials

- Packaging materials

- Waste

- Emissions

In the following, the individual areas in which environmentally-relevant data are already collected and optimized are explained in detail.

Sulzbach Office Site

At the Sulzbach office site, the energy consumption, amount of kitchen waste and paper usage are recorded. In 2015, an energy audit was carried out at the Sulzbach site in accordance with legal requirements. Due to the rental situation, this only resulted in a few potential savings, as the systems technology is located in the building and is not under the control of cosnova GmbH.

Butzbach Logistics Site

The new CNL Logistics Centre was built in 2016 in accordance with the EnEV standard (Energy Savings Regulation). Various other measures were also implemented to make our logistics processes more environmentally-friendly and a Lean and Green program was launched. In addition, an extensive project was carried out to optimize and reduce the logistics waste generated at the site and to optimize the use of shipping cartons.

CO2 emissions in the cosnova business model in general:

The business model of pure contract manufacturing requires long, upstream transport routes, as the globally manufactured products have to be transported to the warehouse of the logistics partner CNL. The data collection of these transports is currently not possible, which severely limits the concrete possibility of influencing these outsourced processes. The following processes are affected:

- Outgoing transports to our distributors: Deliveries for international transports are collected, so we have no influence on the execution of the transports (INCOTERM: ex-factory).

- Outgoing transports to decentralized customers: These are carried out by our service providers. Both concrete CO2 and primary consumption data cannot be provided by the service providers. An average analysis of all parcel deliveries to retail outlets is not in proportion to a more precise calculation of emissions from warehousing processes and central customer transports.

- Outgoing flows of goods, which are collected directly by the customer ex-factory: These transports are handled by the customers themselves.

- Incoming flows of goods from our suppliers to our warehouse: These transports are handled by the suppliers themselves.

Emissions at the Sulzbach site:

Relevant CO2 emissions at and due to the Sulzbach site are mainly caused by business trips, electricity consumption and heating as well as, to a comparatively small degree, by the company's own vehicle fleet, the disposal of the waste produced and the commuting distances of employees.

Emissions at the Butzbach logistics site:

Relevant CO2 emissions at the logistics site are caused by electricity consumption, gas consumption and downstream transport routes. The construction of the new logistics center has made it possible to implement a number of CO2 -reducing measures. Gas consumption and the resulting emissions have decreased significantly compared to the old site, despite the larger usable area in the new warehouse. The reduction in gas consumption can be explained by the installation of special dark heaters in the ceilings of the logistics center as well as the optimized insulation of the hall ceilings and walls. All of these measures are aimed at reducing energy consumption at the logistics site and conserving energy resources. In addition, there will be a conversion to certified green electricity from renewable resources on 01.01.2019.

Energy at the Subzbach site:

The type of electricity as well as the electricity consumption can also be directly influenced in rented office space. cosnova GmbH already switched to green electricity from renewable energies quite some time ago and started implementing smaller energy-saving projects in 2014. These include a comprehensive conversion of the bathroom lighting to motion detectors and, for example, the conversion of daylight luminaires to special motion-activated floor lamps over the entire rented office space.

Energy at the Butzbach logistics site:

During the construction of the new CNL logistics center, all lighting was converted to LED technology due to the higher energy-efficiency of LED lamps compared to conventional light sources.

Water: Water consumption is neither relevant for the Sulzbach site nor for the logistics center and is therefore not recorded.

Waste at the Sulzbach site:

Since the Renewable Energy Sources Act (Erneuerbare-Energien-Gesetz - EEG) came into force, electricity production from biomass has grown strongly. We also participate in this process by recycling the kitchen and food waste from the company's own canteen in a biogas plant. All other waste generated at the site is disposed of directly by the landlord and is not within the scope of control of cosnova GmbH.

Waste at the Butzbach logistics site:

The waste generated at the logistics site is part of an extensive waste optimization and reduction project. In addition to a general waste reduction, we have set ourselves the goal of identifying alternative materials with a reduced ecological footprint as well as of finding the best possible recycling solutions for the remaining waste through recycling or upcycling projects.

Paper at the Sulzbach site:

The paper consumption at the office location is recorded annually, qualitatively it is fresh fiber paper, which is 100 percent PEFC and EU Ecolabel certified. Various interdepartmental projects have been initiated to reduce paper consumption, for example, the introduction of a "chip for all systems" on all printers, which avoids unnecessary printing. Other activities include the general presetting of printers to double-sided printing or the introduction of an electronic invoicing system in the Accounting Department. For two consecutive years, introducing these measures has led to a reduction in total paper consumption of more than 20 percent. In the long-term, cosnova GmbH is aiming for a completely paperless office.

Paper at the Butzbach logistics site:

In order to reduce the paper consumption at the logistics site, further concrete projects have already been initiated in addition to the general aim of reducing waste, which also includes the reduction of paper consumption. For example, by minimizing the wall thickness of the cardboard used or setting up a small internal print shop. With the help of this in-house print shop, assembly instructions and other documents can be printed piece by piece, thus avoiding unnecessary printouts that were previously not avoidable when ordering from external partners.

Cosmetic raw materials:

A wide variety of natural resources in the form of cosmetic raw materials are used to manufacture our products. According to our internal raw material cluster, these include natural substances, biologically modified substances and mineral substances. Natural substances and biologically modified substances have the largest diversity of raw materials.

Looking at the quantitative share of raw materials in the finished products, the category of biologically modified substances accounts for 20 percent of the total raw material share, natural substances for 6 percent and the category of mineral substances for 8 percent. Consequently, one third of all raw materials used have a natural origin or can be considered near-natural.